TERRAPIN Device

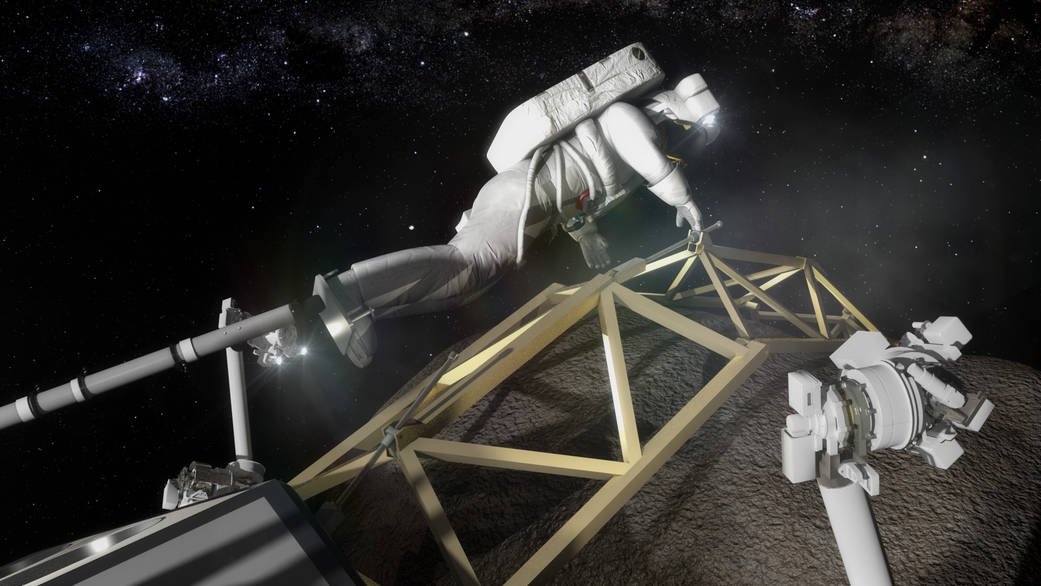

When astronauts explore asteroids in the near future, how will they secure themselves and their equipment to the surface?

2016

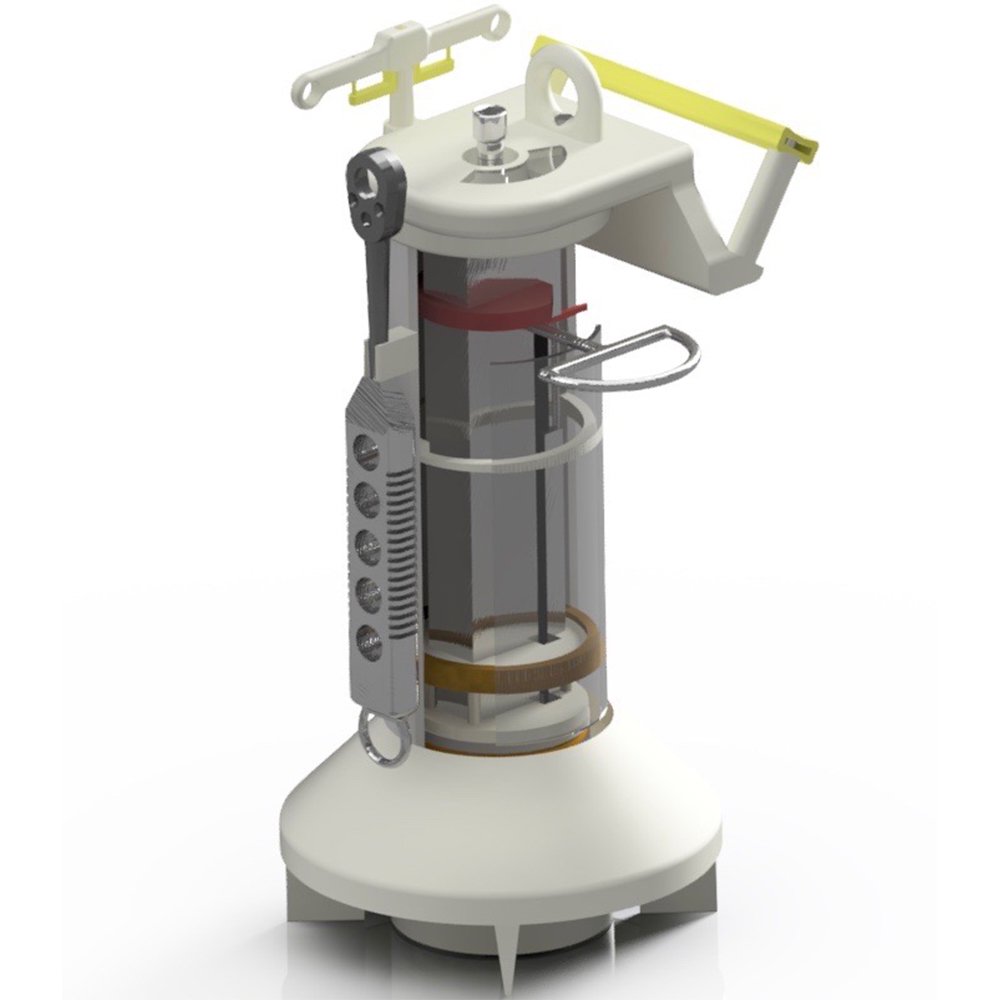

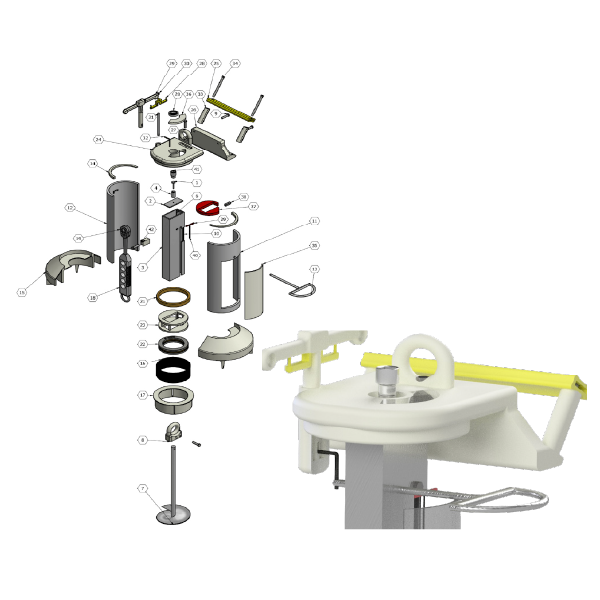

The TERRAPIN (TERRain Anchoring Point InsertioN) Device was a tool designed in cooperation with NASA that aimed to establish secure anchoring points in asteroid regolith.

In the 2010s, NASA started planning the future of American space exploration, with a human presence on Mars being the summit of this journey.

Before this milestone could be reached, many obstacles had to be cleared. NASA created the Micro-G NExT program to collect ideas from university students all around the country, recruiting them to help overcome some of space’s toughest hurdles.

The University Of Maryland’s Aerospace Engineering program selected three students under Dr. Dave Akin to compete in this challenge. The goal of the 2016 mission was to design a tool capable of inserting a tether point into an asteroid’s surface.

The Micro-G NExT program aimed to inspire young students to pursue aerospace engineering and other STEM disciplines. The TERRAPIN Device team visited students of Linganore High School, explaining the project and working with them on a small design project. The team also participated in Maryland Day, an event at the University of Maryland that involved people of all ages in the academic community.

Designing a tool for use in microgravity while being stuck on Earth proved a significant challenge from the start. The team was able to network with experts from the University of Maryland along with engineers at the nearby NASA Goddard Spaceflight Center. These connections provided valuable insight and feedback for the team.

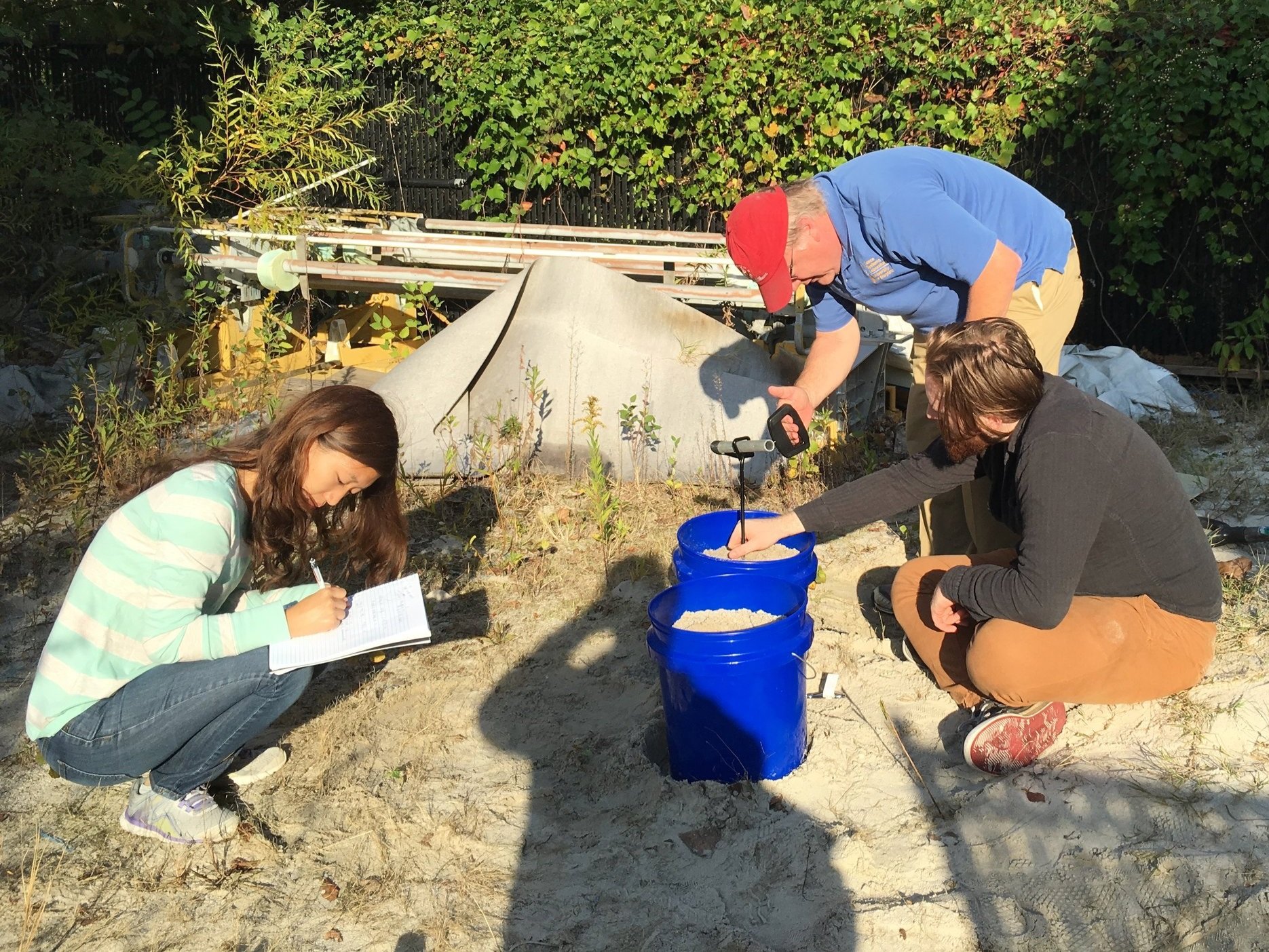

Any movement in space has an equal and opposite reaction. The team began to devise ways to drive an anchoring point down without being pushed away from asteroid surface. We took inspiration from sand augers, which convert rotational force into downward motion using the mechanism of a screw. The team conducted numerous tests using store-bought augers and 3D-printed prototypes to develop the tool.

Throughout the project, the auger design was retained but modified and reiterated constantly. To ensure safe operation, various redundant features were incorporated into the device to ensure that it could not become a hazard during deployment.

Features were also designed to comply with existing NASA guidelines and increase familiarity for astronauts. For example, the tool was made to interface with the ratcheting wrench used in Space Shuttle EVA (Extra- Vehicular Activity) missions and donned a handhold that was identical to those used on the International Space Station.

Once the team’s proposal to NASA was accepted, development of the TERRAPIN Device accelerated towards the z test at the Neutral Buoyancy Facility at Johnson Space Center, Houston, TX. Multiple manufacturing processes from 3D printing to CNC milling were used to fabricate the prototype.

Throughout a one-week process at Johnson Space Center, the tool was reviewed by astronauts and NASA experts. Finally, the TERRAPIN Device was used by expert test divers at the Neutral Buoyancy Facility at Johnson Space Center, Houston, TX (below). The divers reported positive experiences using the tool and it exceeded the requirements of the test, validating our design philosophy.

Tools/Materials Used:

CNC Mill, for final prototyping

Stratasys uPrint SE 3D Printer, for final prototyping

Autodesk Inventor and AutoCAD, for 3D model and renders

Workshop Tools (belt sander, bandsaw, cordless drill, drill press, Dremel tool) for prototype manufacture

Thank you to:

Dr. David Akin, University of Maryland Neutral Buoyancy Research Facility

Brian Roberts, Automation and Robotic Systems, NASA Goddard Space Flight Center

Mark Lastova, Instructor, Project Lead The Way, Linganore High School